The newly launched RICOH TH6310F that uses a thin film piezo actuator (a kind of piezoelectric transducer that creates mechanical deformation by applying a voltage used for jetting drops of ink), and is a key component in digital printing systems, is an flagship model among the company’s family of industrial inkjet printheads. Using its high firing frequencies, the new printhead is the most productive inkjet models by RICOH for both single and multi-pass applications. It uses Micro-Electro-Mechanical-Systems (MEMS): a general term for miniatured electro-mechanical devices or technology. It enables high jetting accuracy, while its unique nozzle layout yields print quality even at high gap printing (printing that requires distance between the printhead and the media, such as printing on uneven surfaces) required in textile and other applications.

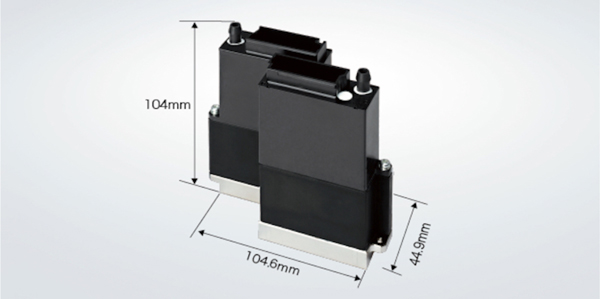

In the industrial print market for textiles, corrugated cardboards, labels and other products, there is an increasing demand to meet a variety of customer needs, including smaller run sizes and shorter delivery times. These needs are being addressed by the rapid digitalisation of industrial print, contributing to overall greater flexibility, efficiency and productivity. These shifting and expanding requirements call for increasing demand for inkjet printheads that offer higher productivity and high-resolution printing. Ricoh’s unique highly-integrated design using MEMS technology has achieved a 6.6cm printing width with an array of 1600 nozzles (staggered array of nozzle rows with 75npi per row) by configuring two modules of 100 x 8 rows.