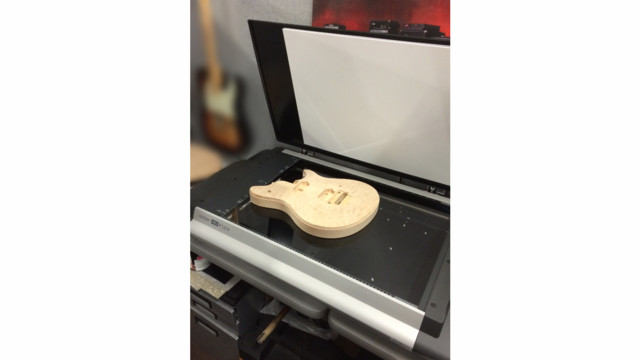

Contex, one of the leading wide-format imaging and scanning solutions, announces that long-time customer and major guitar company recently upgraded to the Contex HD iFLEX flatbed scanner for its 3D manufacturing workflow. The famed guitar company relies on the Contex scanner to capture digital representations of the body, neck, and pickguard of new and old guitars, then creates 3D models using SOLIDWORKS software. A CNC machine takes the information from the 3D software to create new prototype guitars. The Contex scanner eliminates some of the manual work in the manufacturing process, while maintaining the integrity of the company’s craftsmanship.

The guitar company upgraded from a decade-old Contex flatbed scanner to the HD iFLEX, which is regarded as the most flexible flatbed in the market. The HD iFLEX A2/C-size flatbed can scan up to A1/D-size documents in four seconds. The faster solution makes the guitar company’s manufacturing process more efficient, thus increasing productivity. In fact, having a wide format scanner in-house is a must for fostering productivity and efficiency in a manufacturer’s production process. It improves workflow for the better.