XAAR has enhanced its fluid development and optimisation process to help manufacturers and OEMs fast-track inkjet system development, reduce costs and drive innovation. Leveraging its printhead technology and expertise in handling inkjet fluids, the new flexible and scalable process gives customers a faster, more efficient route to market, whether they choose from XAAR’s wide range of approved fluids or develop their own with dedicated waveform support. By minimising early-stage capital investment and enabling early fluid verification, customers can reduce risk, accelerate development cycles and deliver high-performance, disruptive solutions.

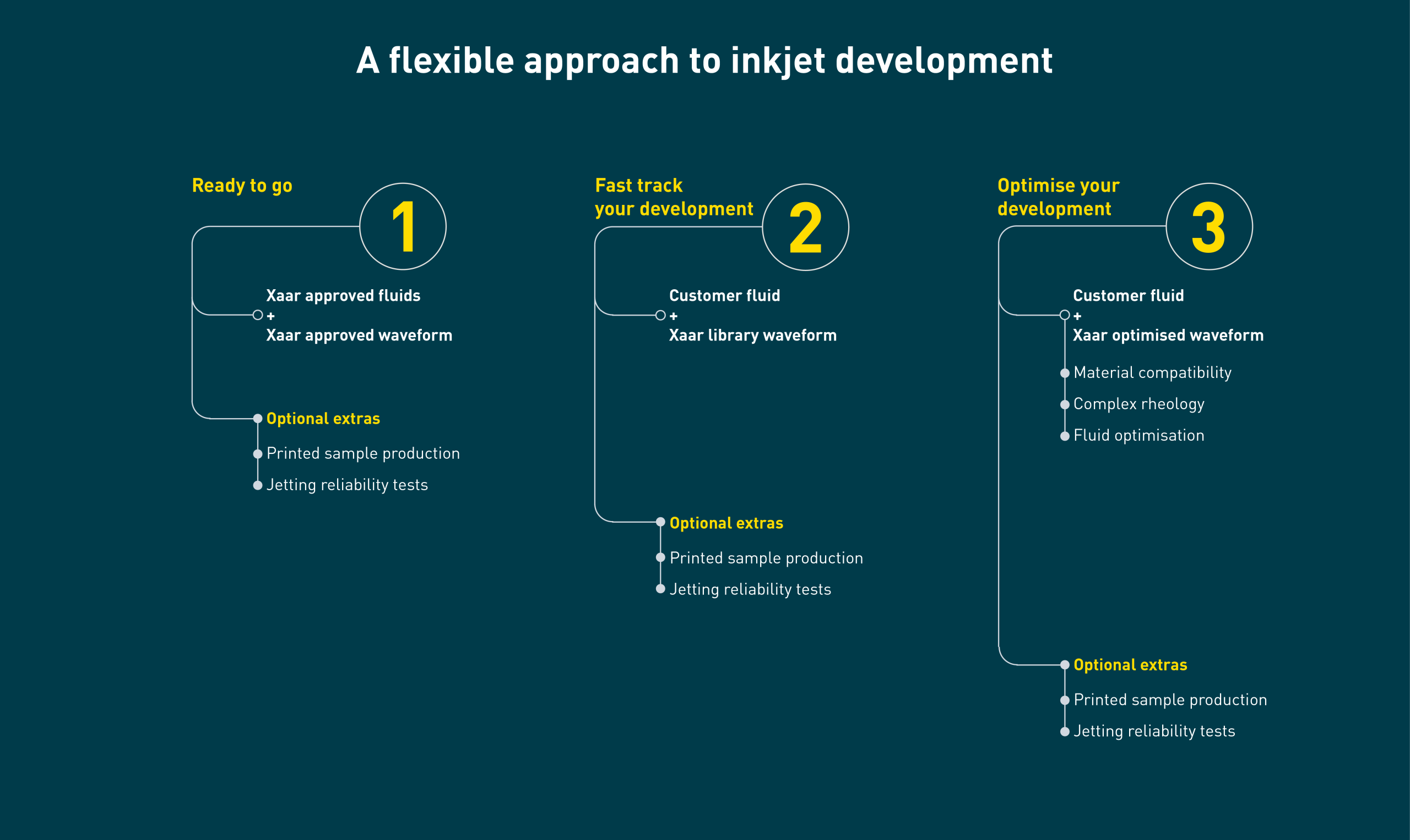

In addition, XAAR’s unique capability to jet challenging fluids, including those with high viscosity, particle loading or large particle sizes helps speed development of inkjet’s use in innovative applications. The new process supports three key pathways for development. The quickest route is to choose from a portfolio of pre-approved fluids, each supplied with tailored waveforms and confirmed compatibility with XAAR printheads. These fluids have already been optimised for a range of applications, allowing for rapid system integration.